Home About us Contact us Protuner Loop Analyser & Tuner Educational PDFs Loop Signatures Case Histories

Michael Brown Control Engineering CC

Practical Process Control Training & Loop Optimisation

LOOP PROBLEM SIGNATURE PART 2-21

DYNAMICS OF MORE COMPLEX PROCESSES

POSITIVE LEAD INTEGRATORS - PART 2

In the Part1 of this article, the dynamics of positive lead integrators was given, and examples given of some applications where the control person could expect to encounter them.

One generally finds processes with these dynamics very badly tuned, and usually extremely slowly. This is largely due to a lack of understanding of the properties of these dynamics. The positive lead is very fast, so combined with the fact that the process is integrating; it makes it very difficult to run these processes in manual. Also bad tuning can easily lead to instability.

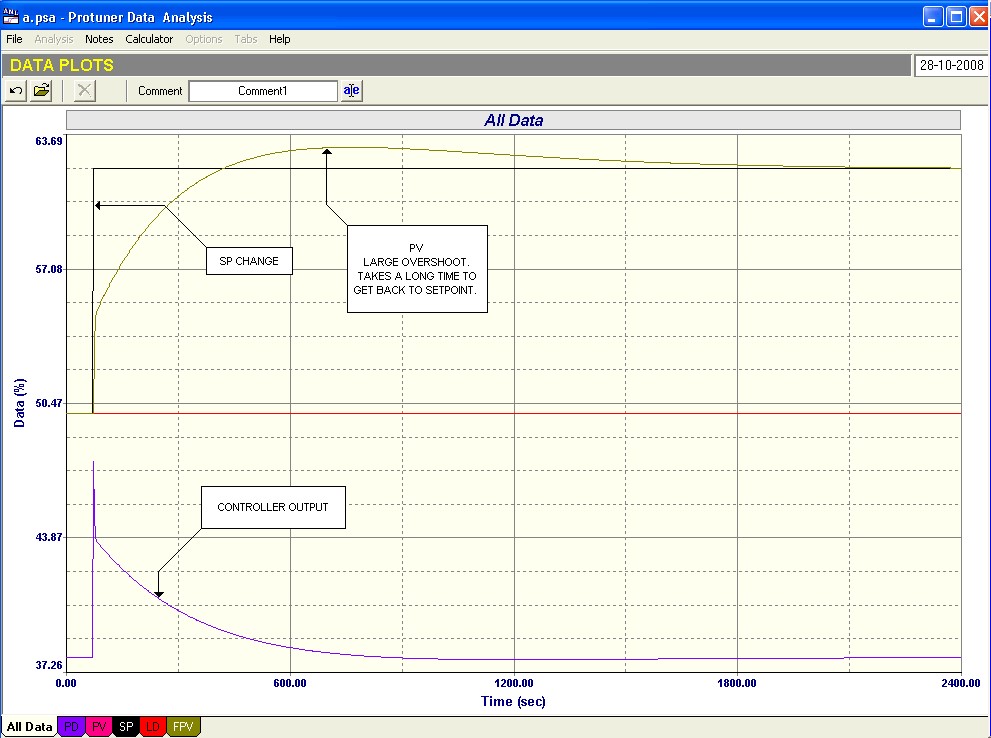

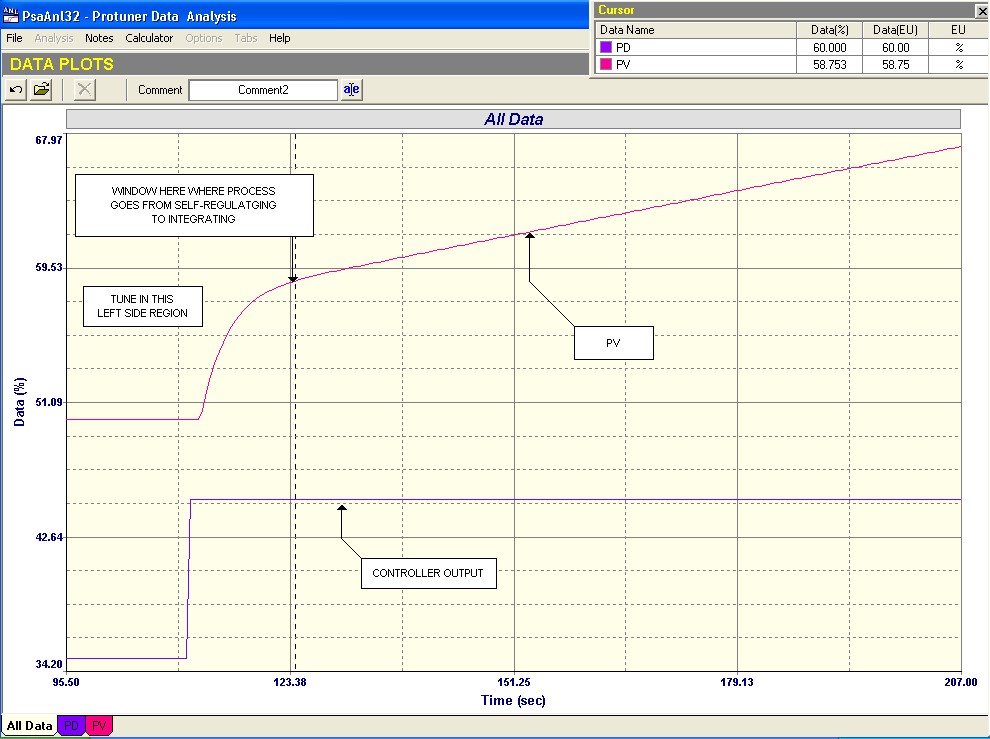

Figure 1

Figure 1 shows a closed loop test performed on a steam drier at a paper plant with the “as-found” tuning. It shows the response of the steam pressure to a step change in setpoint. It is very slow with quite a large overshoot, and it takes a long time for the process to get back to setpoint. As will be seen later it is far from satisfactory and would not follow the setpoint signal sent from an advance controller at all well.

The problem with the dynamics is the positive lead. Without the lead it would behave as an ordinary integrating process, which can be controlled very well. One solution would therefore be to cancel out the lead by using a filter on the PV, with its time constant set equal to the lead. For more details on this refer to Loop Signature P2-15 on positive lead self-regulating processes, where the same technique was used. (This article can be accessed on my web site (www.controlloop.co.za). This solution works extremely well as far as load changes are concerned. However any setpoint change will result in unbelievably huge overshoots, as positive leads in integrating systems are very large. (The reasons for this are also discussed in Loop Signature P2-15, and in Loop Signature P1-20).

This solution is no good at all for the paper machine steam drier application where the pressure has to follow a remote setpoint. Another solution had to be found, which is illustrated by a delightful story told to me by an American friend of mine. I cannot guarantee it is true, but it’s fun.

Apparently there was this enormous paper plant in the American Wild West. A cowboy on a beautiful white horse rides up to the plant, ties his horse to the hitching post, goes in and says to the Process Manager:

“I will tune your drier loops so well that they will follow setpoint changes from the advanced control system with absolutely negligible variance, but I want $35,000 per machine.”

It is said he became a millionaire before people found out how he did it. So this is how it works:

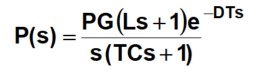

The transfer function is:

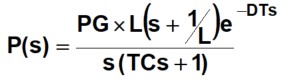

If L>>1 & if L>>TC then:

Now,in the short term:

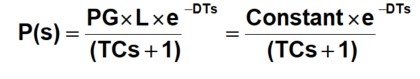

The s’s then cancel and we are left with:

Which is the transfer function for a first order lag, dead-time, self-regulating process.

So the process essentially starts off as a self-regulating process, and then turns into an integrating process.

Now if you remember right back in the Part 1 Loop Signature series an important rule of thumb was given:

“ALWAYS TUNE A PROCESS THE WAY IT STARTS REACTING TO A STEP CHANGE". If it starts off as integrating and turns into a self-regulating process, then tune it as an integrating process, and if it starts up as a self-regulating process, and then turns into an integrating process, tune it as self-regulating.

This is completely reinforced by the example of the density control on the coal and stone separation plant given in Part 1 of this article, which was the previous one published. You will remember that I originally was convinced that the process must be self-regulating, and was extremely surprised when it turned out to be integrating. So that was in fact a classic example of a true self-regulating process that did turn into an integrator as the lower density magnetite was returned to the tank.

Thus we can understand that our cowboy was tuning the pressure controls on the driers as self-regulating processes.

How do you do the actual tuning?

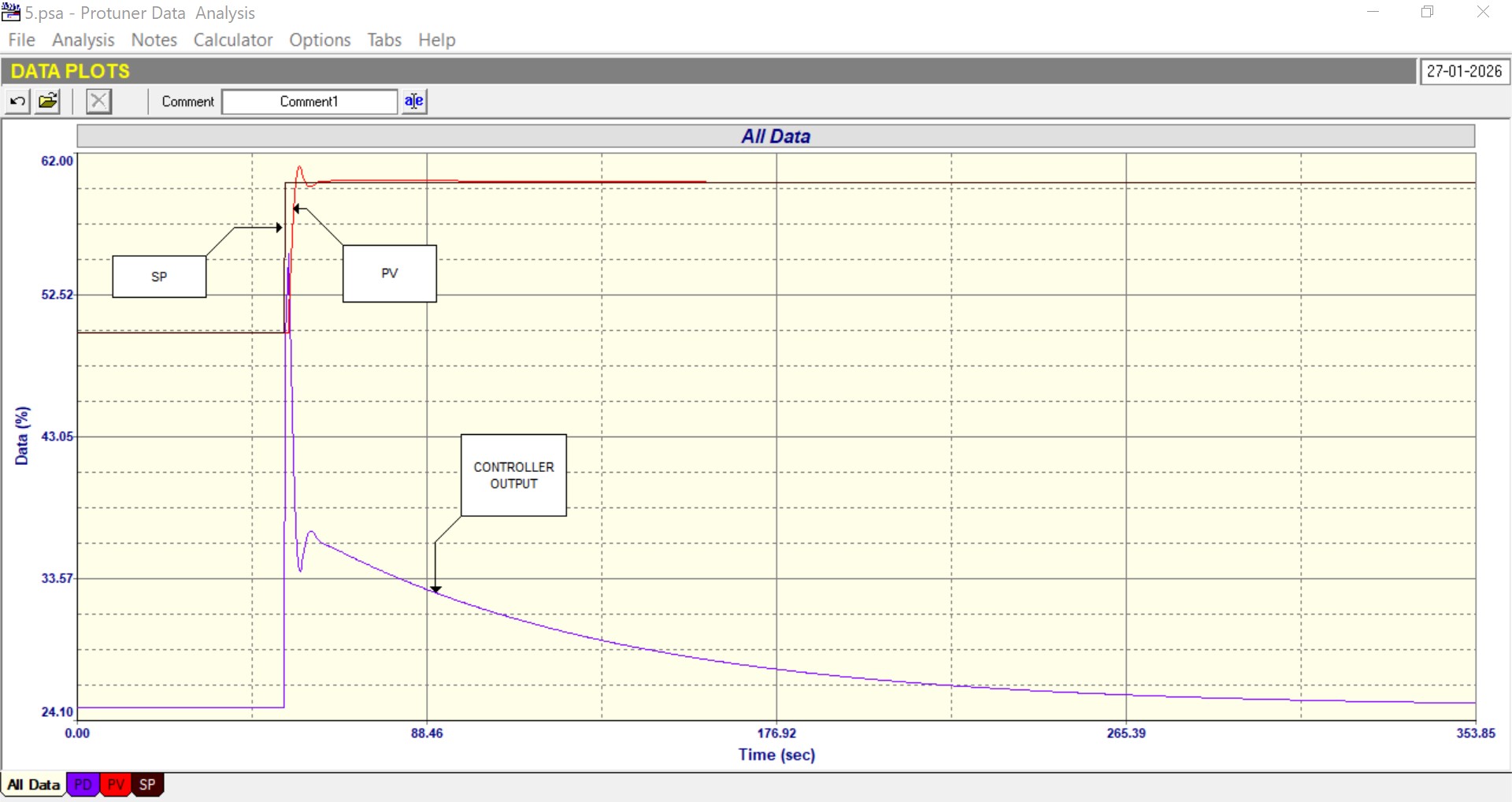

Figure 2

Referring to Figure 2 you look at the open loop step response, and you put a window at the point where you think the process is changing from self-regulating to integrating. The exact point is not highly critical. You then tune on the left hand section as a self-regulating process.

Figure 3

The closed loop response using such a tuning is given in Figure 3. The result is absolutely amazing. It’s like magic. The tuning is probably a thousand or more times better than the original tuning shown in Figure 1. My American friend who told the cowboy story says that as far as he is concerned it’s the closest that a control engineer will ever get to “walking on water”. I personally call it my “party trick.”

I once was teaching a course on which two of the delegates were from a large tissue paper plant. One was the Process Manager, and the other the Control Engineer. After I had gone through this section on positive lead integrators, I expected to see them really pleased and excited. Instead they were muttering to each other with glum faces. On querying why, the Process Manager said:

“Its all very well doing that on a simulator, but you could never do it on a real drier, particularly on a large diameter Yankee Drier on a tissue machine, as the thermal stress would crack the drum. So as far as we are concerned its just pure theory.”

Now I must mention that I have tuned probably dozens of driers including a Yankee Drier, and to date have never cracked a drier’s drum, and I hopefully never will in the future either. However there is a very important point, which I want to stress here, as I am always encountering peoples’ resistance to step changes.

Firstly as a general rule one does not normally make many set-point step changes during normal plant operation in the typical continuous process type plant. The ones I am always showing in these articles are generally only made when testing tuning response. The vast majority of controllers are there to keep processes on setpoint during load changes, and in some cases, to follow remote setpoints from advanced control schemes. These are both normally really slow moving. Secondly if you don’t have reasonably fast tuning to keep control variances to a minimum, then you are not going to have good control. (Remember that fast tuning means fast response, and does not mean cyclical responses with over and undershoots. The majority of the loops I tune are generally around critical damping, with no overshoot at all, and most of these tunings are dramatically faster than the original “as-found” tuning.)

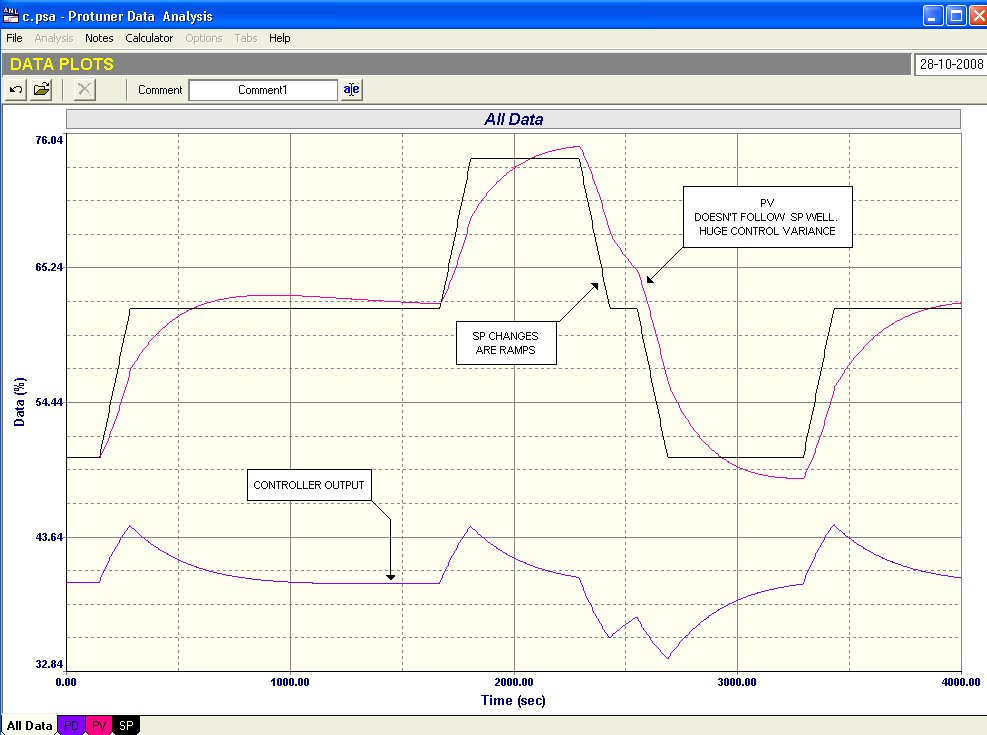

Figure 4

A really dramatic illustration of this point is given in the next figures, which show response to slow moving ramped setpoint changes. (Please note that the test period was over an hour so the setpoint changes are indeed slow.) The first one is seen in Figure 4. This is the steam drier pressure control with the tuning as seen in Figure 1. The PV never gets to setpoint except where they cross. One can see that the control variance is huge, and must be costing the plant a lot of money, as the PV does not follow the SP properly.

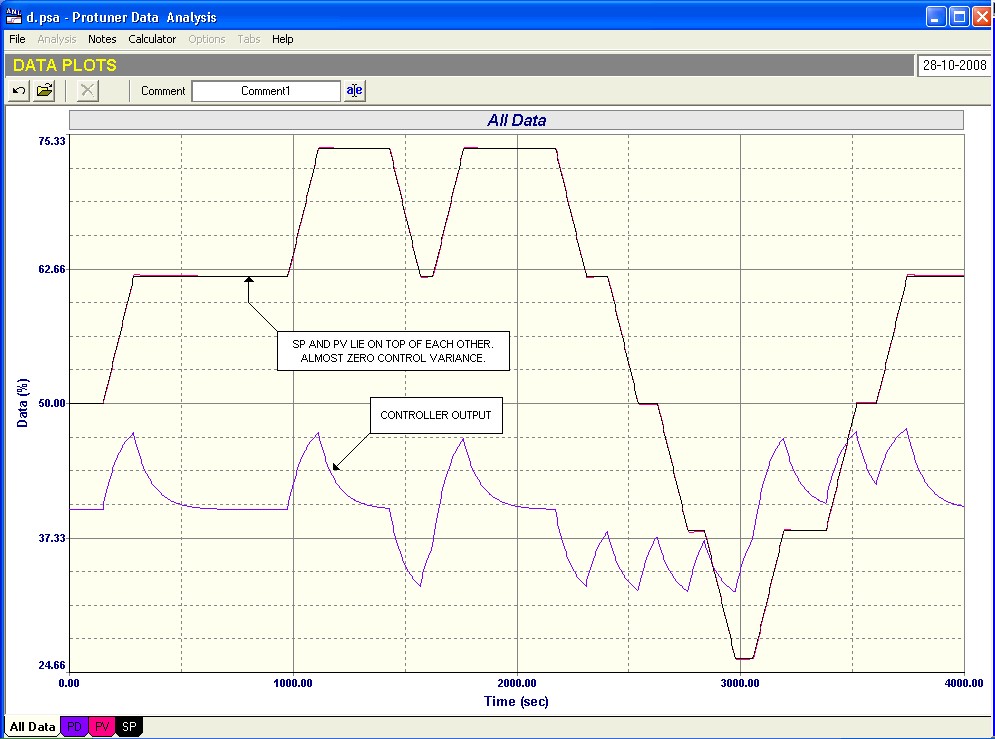

Figure 5

Figure 5 shows the response with the new tuning as was shown in Figure 3. It’s really almost unbelievable how good it is. It effectively has zero variance, which is almost unheard of for feedback control.

So if you ever are called on to tune a positive lead integrator, now is your chance to be a hero in the plant!

Just one word of warning: Make sure that the valve is working properly and following what the controller is wanting. Any hysteresis and similar problems can create havoc. (Refer Loop Signature Part 1 articles on valve problems.)