Home About us Contact us Protuner Loop Analyser & Tuner Educational PDFs Loop Signatures Case Histories

Michael Brown Control Engineering CC

Practical Process Control Training & Loop Optimisation

CONTROL LOOP CASE HISTORY 164

MORE ON VALVES THAT DON'T CONTROL PROPERLY

I often publish articles showing valve problems. One of the reasons for this is that I don’t think a lot of people understand that valves are generally responsible for about 75 – 80% of all control loop problems. When it comes to relatively fast control loops such as flow, valve problems can often be “got around” as feedback control is so powerful and provided that the controller is well tuned, it sometimes manages to overcome a lot of the valve problems.

A good case in point was a splitter reflux flow control loop in a refinery, which had a really bad valve. The operators were battling to control it, and had the loop in manual, but even then, they found it extremely difficult to get the flow to reach a stable value at the correct value.

Figure 1.

Figure 1 shows the open loop test performed on the loop. It is extremely interesting as it shows so many problems with the valve:

1. The valve overshoots hugely on closing and opening steps.

2. It is terribly oversized, probably by as much as 8 times which magnifies all the problems as seen on the PV by 8 times.

3. The positioner, valve combination is almost unstable, and at times does go into a cycle.

4. The valve sticks badly at times.

5. The valve performs differently on different steps, which means it is also not repeatable.

When one encounters a control loop with a valve like this, you know that there is no way that one can get proper control, and it is essential that the valve be fixed or replaced. However it is sometimes possible to get some sort of control in the setpoint region by deliberately tuning the controller with fast unstable parameters, in order to deliberately make it cycle around setpoint. This can sometimes help keep the plant working until the valve can be sorted out. This was done in this case, and the resultant limited control cycle can be seen in Figure 2. Certainly not nice, but possibly better than no control at all.

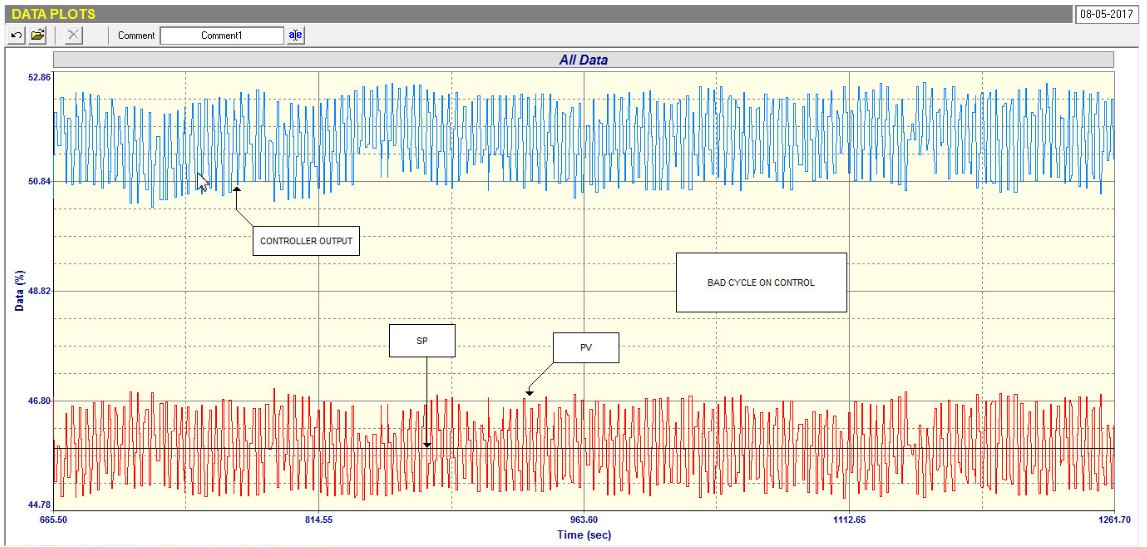

Figure 2.

This solution should be used with caution, as cycling of this nature can sometimes cause problems with other interactive loops. However if the flow loop is a cascade secondary to a slower loop such as level or temperature it will ensure that the average flow going into the process is correct, as the cycle is relatively fast.

The second example in this article deals with a valve that exhibited a “stick-slip” cycle.

Stick-slip cycles are one of the most misunderstood cycles that frequently occur on fast self-regulating loops such as flow loops, and are generally caused by valve or valve/positioner combination problems. At least 95% of plant personnel on observing a stick-slip cycle are positive that it is a tuning problem, and demand that the controller be retuned.

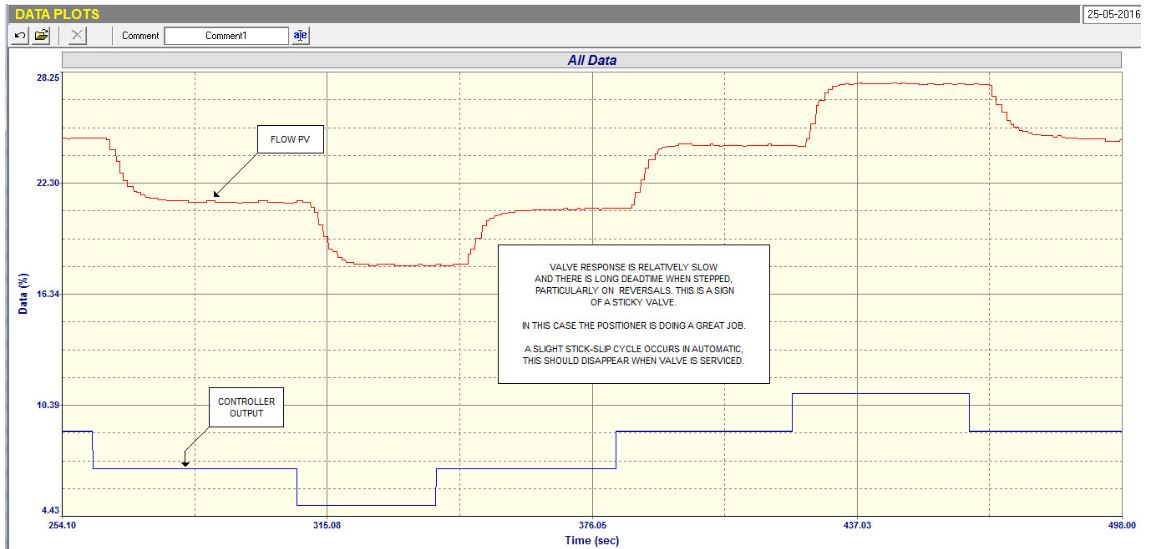

In this case the tuning was pretty good, and it took an open loop step test to analyse the problem with the valve. This is shown in Figure 3. On initial inspection it appears as if the valve is working perfectly, and it appears to follow step changes on the controller output extremely well. Deeper inspection shows that the valve is sticking quite badly as it takes quite a few seconds to respond to the controller’s output step changes. In particular after one reversal in direction it took about 7 seconds before it moved. This far too long for a flow loop which generally has deadtimes of one or at the most 2 seconds at the most. Therefore it is clear that the valve is sticking badly, and the positioner is actually doing a fantastic job in overcoming the stiction and getting the valve smoothly to the correct position without overshoot.

Figure 3.

Flow loops fall into the simplest class of process dynamics as they effectively can be defined as a self-regulating process with a single first order lag and deadtime. The correct pole cancellation tuning to cancel out the process lag is to set the controller’s integral term equal to the time constant of the lag. Once that has been done, one merely has to adjust the controller’s proportional gain to get the required control response that you wish for the particular loop.

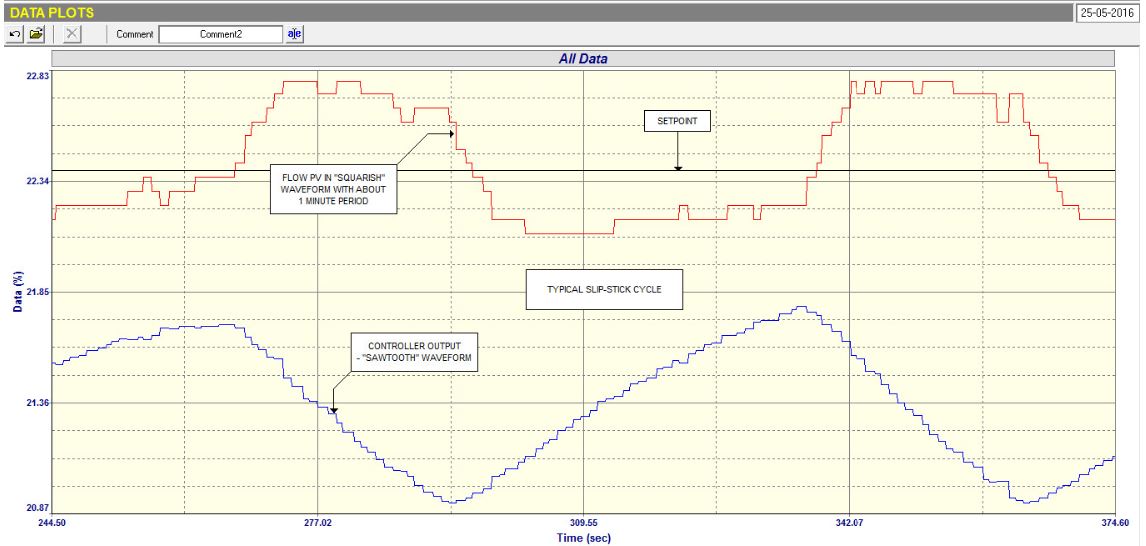

Typically flow loops have lags of around 1 – 2 seconds and similar deadtimes. Therefore the controller also typically needs to be tuned with an integral setting of 1 – 2 seconds/repeat, which is relatively fast. Therefore if the valve sticks as in this case, then the integral term starts what is known as “winding up” which means it sees a constant error and starts ramping up (or ramping down, as the case may be) the output of the controller to try and get the valve to move. This results in an excess movement in the controller’s output in the form of a constant ramp. At the point when the valve moves the output of the controller immediately starts moving in the opposite direction. The positioner sees that the controller’s output is asking for a certain valve position, and moves the valve to that position, but unfortunately that position takes the PV to the other side of setpoint as the controller’s output has moved too far.

The net resultant is a very typical waveform with the controller’s output forming a “saw-tooth” wave, and the PV moving in close to a square wave pattern. These waveforms can be clearly seen in Figure 4.

Figure 4.

Obviously one solution to the problem would be to slow down the integral. However in real life it ends up in an integral that is so slow that decent control response cannot be obtained. Although a lot of people think that flow loops don’t need to be controlled quickly, it must be remembered that many of them are cascade secondary’s, which are there to remove valve problems from the slower primary loop, and the secondary loop really needs to be as fast as possible. Therefore I often suggest in cases like this that if the valve cannot be sorted out quickly, it is better to leave it with stick-slip cycle which in actual fact in many cases is not a major problem as they are relatively slow and small and will not seriously affect the valve’s life, or cause a process problem.

In cases where they can cause problems like interaction or other problems (particularly when the valve is largely oversized), a good solution is to put a small band around setpoint about the size of the amplitude of the stick-slip cycle, and slow the integral down in that band. This is an excellent solution where the flow loop is a cascade secondary.

As mentioned above many people think the slip-stick cycle s a tuning problem and then they detune the controller until the cycle stops. As discussed in a previous article I think of a loop in manual as the ultimate slowest tune. Therefore in general if you slow a loop down far enough it will stop cycling. I refer to this type of tuning as “being tuned into manual”.