Home About us Contact us Protuner Loop Analyser & Tuner Educational PDFs Loop Signatures Case Histories

Michael Brown Control Engineering CC

Practical Process Control Training & Loop Optimisation

CONTROL LOOP CASE HISTORY 166

FEEL AND UNDERSTANDING, OR LACK THEREOF?

I was present at a very interesting discussion the other day with people who are leaders in the automation and control industry. The subject was how jobs would disappear over the next decade or two as automation and robotics progress, and what type of work and professions would be relevant for the younger people coming into the field. The discussion shifted slightly to consider current training methods particularly of young engineers and technicians.

One of the persons present who is a very senior manager in his company which produces very specialised parts for aviation, expressed a deep concern that youngsters are far too reliant on computers and devices particularly where arithmetic calculation is concerned, and don’t have a “feeling” for numbers and values, which can lead to terrible errors. He said they just don’t think about basic things that were “installed” in previous generations of engineers due to their education. He pointed out as one example that it is important for an engineer when designing things and doing calculations to have an innate feeling to ensure that the decimal point is the correct position, or errors of a magnitude or more can easily occur.

I largely agree with his thinking. When I present my courses the following two things always come up:

1. The delegates have to calculate the process gain of a certain integrating process, based on a step change in the controller output away from the balance point. In the calculations it becomes necessary to divide a certain value by 10. Invariably at least 95% or more of all the younger delegates use a calculator for this. This indicates to me that they do not have a “feel” for numbers and values.

2. On many calculations when doing loop optimisation it is not necessary to use very accurate figures. For example when looking at things like process gains of self regulating processes which gives one a rough, but useful idea of the correctness of the valve sizing and spanning of the transmitter, and when measuring and calculating valve hysteresis, you really only need to work at the most with one decimal point. However the graphical measuring device on the recordings in the software I use in the course gives answers with an accuracy of 4 or 5 decimal points. I always tell the delegates to round off the readings to one decimal point when they write the measured values down on their calculation sheet. However they seldom seem capable of doing this and insist of using all the decimal points in the calculations. Once again this tells me that they don’t really have a “feel” for numbers.

Another excellent example of this lack of feel and practical understanding of numbers is the number of decimal points that are often shown on digital displays on operators’ screens, particularly on SCADA displays. My favourite example here is the mass of feed of ore to a mill on a conveyor belt on a gold mine which was displayed on a SCADA screen. The belt weigher used on the belt was a mechanical one. Typically it is accepted that such a device will probably give a reading with an accuracy of between 0.5 to 3% accuracy of full scale, which in this case was 600 tonnes. Basically this means that at best the reading would be accurate to ±3 tonnes. The person who had implemented the displays on the SCADA had used a standard digital display block in the software that gave 8 digits. He had put a decimal point after the third most significant digit, so that at full scale the display read 600.00000!

The average person, particular operators but also some of the less should we say “perspective” metallurgists and instrument practitioners believe the figure displayed as true accuracy. “Hell, it is a computer. It can’t be wrong”.

Now one practical consequence from this is that because the process signals from belt weighers are extremely noisy with a noisier amplitude of typically 8 – 10%, it becomes impossible to read the digital display as the figure is jumping around the whole time. To overcome this problem the instrument technicians on site had inserted an absolutely enormous lag filter with a time constant of close on 2 minutes. This of course allowed a lovely steady display, but gave extremely erroneous readings particularly when being integrated to give a total feed.

Basically these examples illustrate the lack of basic understanding that was being referred to earlier.

Another point was raised by a senior manager of a company that writes control software was that very few instrument and control practitioners working in plants these days have any real idea and feel on how to tune PID controllers, and this doesn’t really matter too much as nearly all modern controller software contains self tuning algorithms. Therefore is it only really necessary to call in a an optimisation expert if they encounter some serious problem?

Unfortunately, this is most often the thinking of plant managers I have been trying to change this thinking for the whole of my professional life in loop optimisation, and have written many articles on this in the past, but just to list a few of the most important points.

1. Feedback control is probably one of the most little understood subjects in the engineering world.

2. At least 85% of control loops in industrial control systems worldwide are operating inefficiently in automatic.

3. Generally approximately 50% of all control loops have some problem in them which the plant people are generally not aware of.

4. The biggest fallacy in plants is the popularly held idea that tuning will solve all the problems. In fact tuning is the very last thing that should be done after first analysing the control loop, finding all the problems, understanding the process dynamics, and then applying the best tuning to fit the control requirements.

5. Most control courses deal with the mathematical and theoretical aspects of control (which are very complex), and deal very little with practicalities, which few lecturers are really aware of themselves, as many of them have had little plant experience

6. When it comes to the actual tuning, sadly very few tuning packages work very well, and are based on making very imprecise and inaccurate models of the dynamics, and as a result give tuning which is most often far from ideal.

It is very difficult in most cases to present financial evidence of what improved controls can do to the “bottom line”. Most plants have been running the same way for many years, and senior managers have very little interest in trying to improve the controls. I have seen a few cases where plants having properly optimised the controls and scientifically measured the benefits have improved their ROI (Return On Investment) significantly.

In general I find it very hard to understand how plants pay a fortune for sophisticated control systems, and then are not prepared to invest a relatively small amount in ensuring they work optimally. Surely it would pay them to have at least one or two staff members who can optimise controls?

What is Not Good?

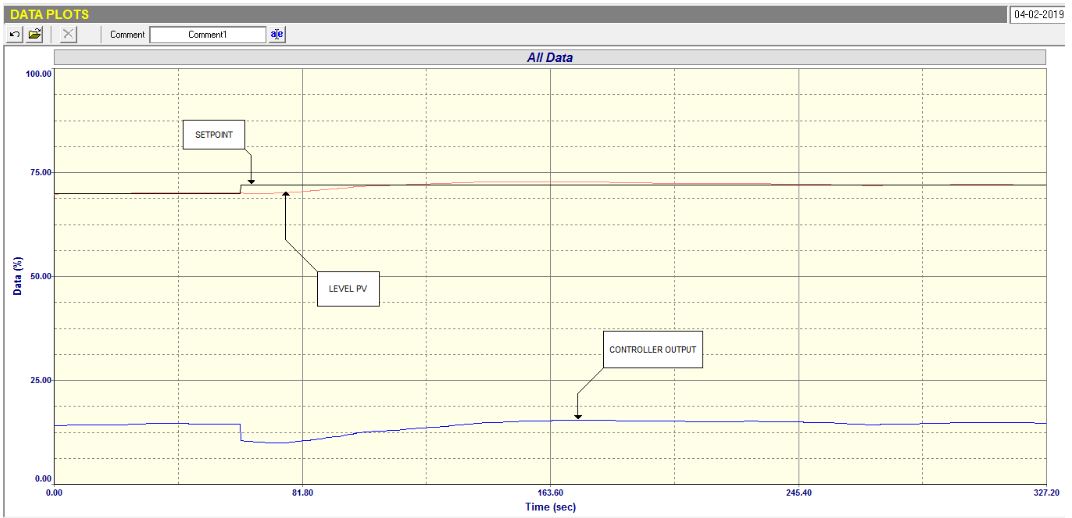

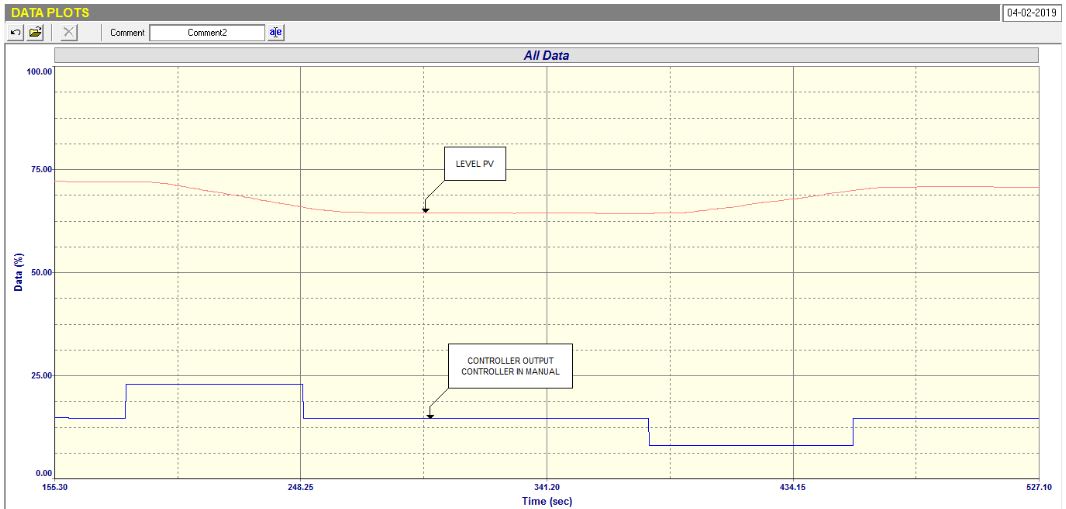

Further to my previous article where I suggested you test your analytical capabilities, I have included a couple of figures showing an open and a closed loop test on a level loop which was working at pretty much the normal load. The loop is actually working very well. (Figure 1 is the closed loop test and Figure 2 the open loop test). However there is something that is not really good in the loop and which could cause problems, and this can be seen clearly in both the tests.

As I do not have much space left, I will give the answer in the next article which should be published in two months time.

Figure 1.

Figure 2.