Home About us Contact us Protuner Loop Analyser & Tuner Educational PDFs Loop Signatures Case Histories

Michael Brown Control Engineering CC

Practical Process Control Training & Loop Optimisation

CASE HISTORY 200

THE FINAL CASE HISTORY - DESUPERHEATER CONTROL PROBLEM

This is the 200th article I have written in this Case History series and it is the last, as I have decided to leave the control arena and settle down in new and quieter pastures.

For this final article I have chosen to relate a problem that existed in a desuperheater temperature control on a boiler in a petrochemical refinery.

For those who deal with boiler controls you will know that the desuperheater final outlet temperature is extremely important for all the downstream processes that use steam. In particular, good control on steam temperature is vital for distillation column temperature control.

On big boilers there are often several desuperheater stages. In this particular case there were 2 stages. A very common control technique is to set the temperature control of the first stage as primary controller and then to use the temperature control of the second stage as a cascade secondary. It is then good practice to cascade this secondary stage to the spray water flow control. However in this case it was not done, and the PD (controller output) of the secondary controller was fed directly to the spray water valve.

The problem related to the fact that the second desuperheater stage was cycling badly. The cycle had a period of 103 seconds and with a range of nearly 20ºC. This was really unacceptable for this control and was causing all sorts of problems for processes relying on the steam. Production had flagged this loop as urgently needing correction.

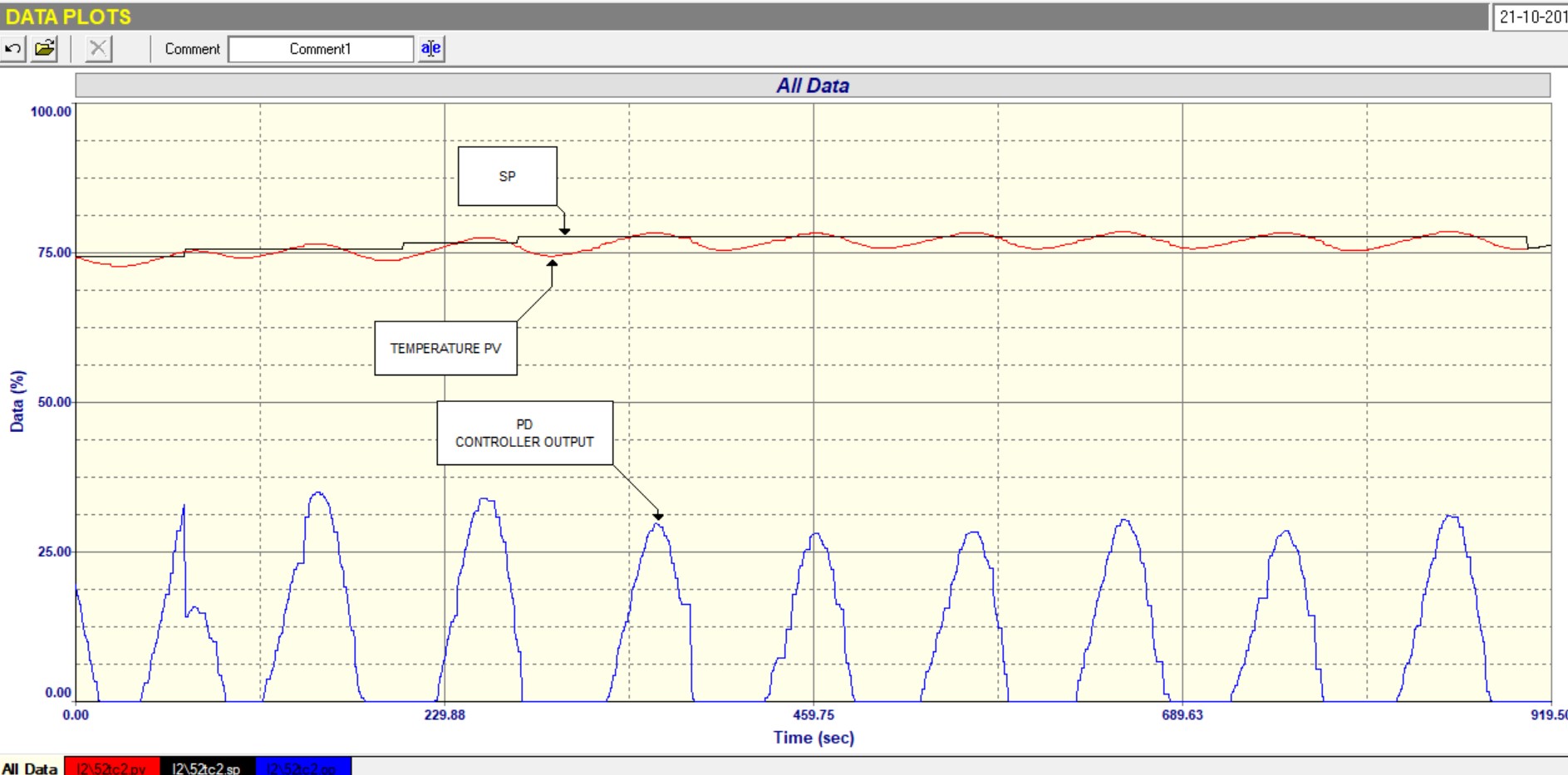

Figure 1

Figure 1 shows the closed loop test on this loop with the controller on local setpoint and in automatic. Of extreme interest is the behaviour of the PD (controller output) which appeared to be shutting down and then opening up in “a half cycle” before shutting down again for a while before repeating the half cycle indefinitely.

This behaviour is often indicative of instability due to bad tuning. However the C&I team at the plant had tried retuning the controller many times without success. All that happened is that they could slow down the cycle or speed it up, but couldn’t stop it.

I have lost count of the number of times I have said that trying to correct problems by merely trying to tune the controller more often than not, is a waste of time. One must firstly analyse the loop properly and again many of my articles and teachings have gone into the various steps one must take before finally tuning.

In this case when I was asked to come and see if I could sort out the problem, I did all the necessary work required for proper optimisation and on examining the control strategy I immediately noted that the output of the controller was connected directly to the spray water valve, and that they had not installed a further flow cascade flow control loop. After going into the plant and examining the physical setup we found that a flow transmitter was in fact installed in the spray water line, but was not being used. We then connected it to the panel and performed an open loop flow test to check the valve performance. This is shown in Figure 2.

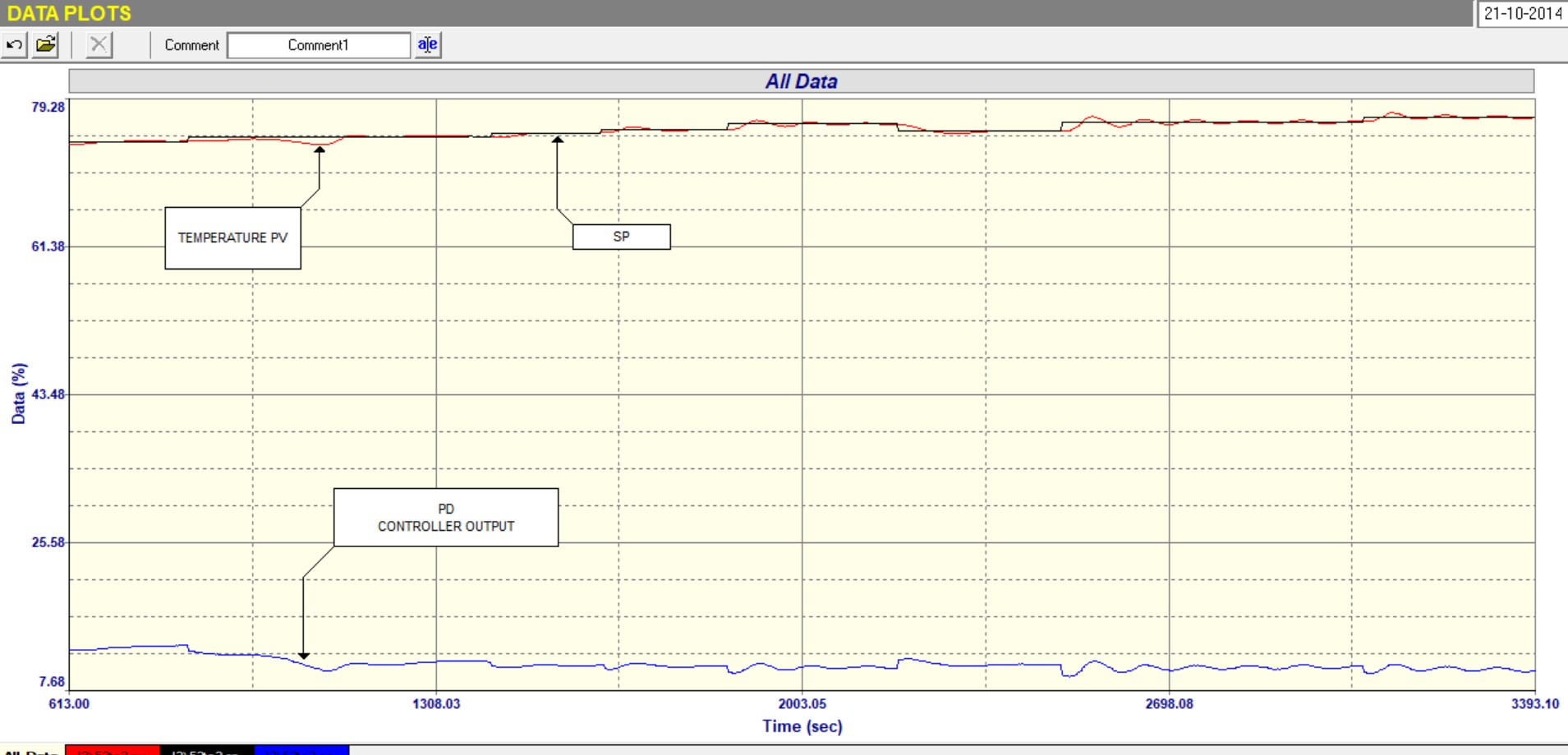

Figure 2

This test immediately indicated that there was a huge valve problem, namely that the valve only opened when the PD got to 10%, and the flow immediately jumped from zero to 18%! The same thing occurred on the valve closing. This means that there is no way of maintaining a modulated flow between zero and 18%, which would definitely cause cycling if the flow needed to be in the low region, which in fact was where it would normally be in normal load conditions.

The next thing that the test showed was that the tuning in the controller was completely unstable. The existing tuning was P = 17 and I = 1.5 minutes/repeat. The correct tuning was P = 1.1 and I = 1.0 minutes/repeat. However if it had been used with the valve problem, it would have made the cycling even worse and much slower.

It turned out as it was felt that the valve could not be fixed and really needed to be replaced. However a new valve would take several weeks to arrive. To try and overcome the problem until the new valve could be delivered, and as a flowmeter was already available, it was decided to install a flow loop cascaded from the second desuperheater stage temperature controller. This was done and when tested the flow loop, which had very fast dynamics as compared with the temperature loop, the new control system actually worked pretty well. However it can be seen that because of the valve problem the flow control acted almost like an ON/OFF control, but this time with a cycle so fast that it managed to more or less get the correct averaged flow into the desuperheater

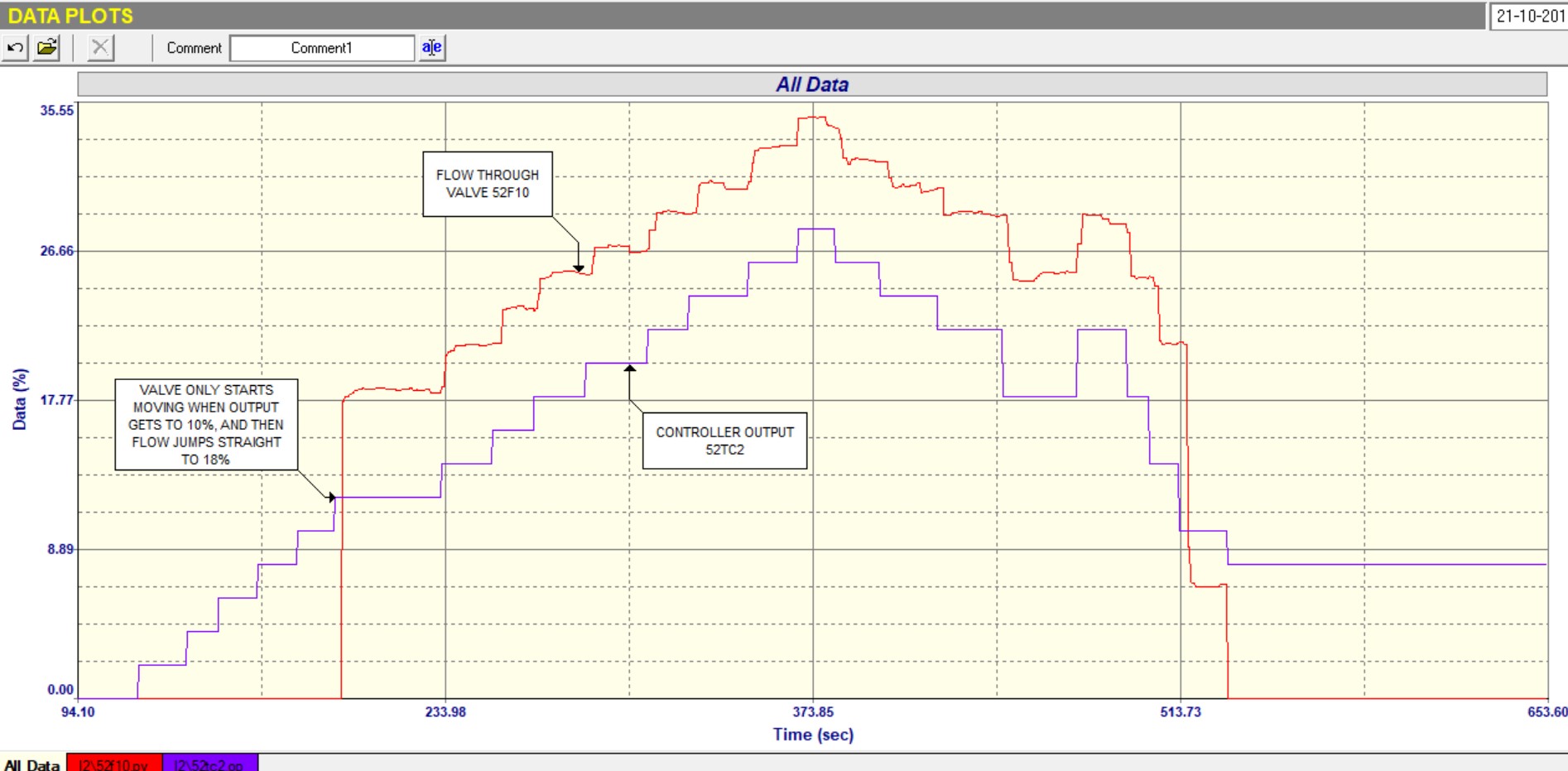

Figure 3

Figure 3 shows the final closed loop test on the temperature loop. (Unfortunately the flow recording is not shown in the figure). It can be seen that the temperature PD was working at around 10% and although at times a small cycle did occur, it did not affect the temperature too much, and the cascade control kept the temperature to within ±1ºC of setpoint which was more than acceptable.

Obviously this was not an ideal solution as the valve would probably have not lasted terribly long with the way it was cycling, but it was hoped it would last long enough until the new valve could be installed.

Once again this is such an important example of why cascade control should be used on important loops with slow dynamics. In this case the valve problem would also have been picked up much sooner.

I will finish off by saying that after all these years of "preaching" practicalities of control, I am disappointed that so few plants still recognise the importance of optimising their base layer controls properly.

I also maintain that my findings over the years which in my opinion are still absolutely valid:

- Approximately 85% of loops worldwide are working ineffectively in Auto.

- 50 to 70% of all loops have equipment and/or design problems, which plant personnel are usually completely unaware.

- Less than 5% of loops really work well in automatic.

Therefore I sincerely hope that more process companies will come to realise how important it is to properly optimise their base layer loops. It could save them huge amounts of money and help to improve productivity. Also their advanced control systems would operate much better.